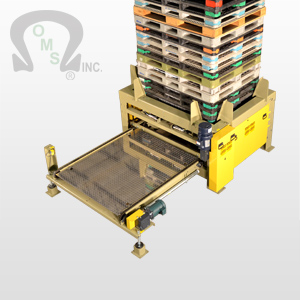

Production Line Level Infeed Bulk

The O.M.S. Production Line Level Bulk Palletizer Model Series 500, 600, 700, 800 and 900 are offered semi-automatic to fully automatic.

Eye level operation provides easy access and monitoring by personnel performing other in-plant duties. In various plant layout applications, the monitoring person attends to more than one O.M.S. “Smart” System. In addition, the monitoring person can replenish the tier sheet, picture frame and pallet dispensers at periodic intervals and also attend to the strapping and wrapping machines. In many plants, that same person also prints out bottle type/size identification labels affixing such to the finished product pallet loads and still has time available for other tasks. The operating labor cost savings are limited only to the extent of one’s applied imagination.

When your company’s future depends on success – Choose OMS

Tech Specs:

Production Line Level Infeed Bulk

OMS is an industry leader with products that show it.

- The O.M.S. System offers a superior approach, forming layers and pallet loads.

- Rows of containers (bottles, jars, cans, etc.) Are asynchronously processed.

- Multi-row infeed systems are equipped with separation lane dividers to ensure positive container control.

- Containers are individually counted to form an exact quantity per row.

- The rows are also counted to form an exact number for a given pattern array(s).

- The O.M.S. System provides automatic staggered (nested) pattern forming.

- Layers are individually processed and maintained from grouping throughout the palletizing cycle.

- Automatic layer retainer guides provide for reliable pallet load stability. Each layer of containers is gently yet firmly retained on all four sides and bottom during layer handling and stacking. In essence, the layer is encapsulated during the entire transporting and delivery cycle.

- The layer sheets are conjointly transported with each associated layer, to include combination top layer sheet and picture frame. The automatic retaining guides further maintain layer sheet and picture frame to container layer unity. The layer plate systematically extends forward, overlapping the previous layer (closing the gap) for smooth transfer flow. A retainer mechanism achieves positive control of the preceding layer sheet.

- Many options available.

Good place to link to the patents page from.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec laoreet quam odio, vitae consectetur diam semper quis. Proin ultrices consequat elit quis fermentum. Aliquam ultrices arcu pharetra magna molestie, vel feugiat erat convallis. Nulla ac tincidunt ligula. Morbi bibendum ultrices nisl, eu bibendum leo laoreet eget. Morbi libero leo, pulvinar id congue quis, dapibus ac nisl. Sed lacus tortor, dictum id massa ut, fringilla aliquam tellus. Nunc ut nunc sit amet purus porttitor ornare. Donec laoreet lacinia massa in faucibus. Quisque rutrum tortor et erat ultricies, interdum tristique nulla iaculis. Nullam auctor nisi nisl, ac dignissim urna mollis a. Proin pulvinar elementum velit. Duis in erat condimentum, pellentesque orci at, luctus urna. Quisque bibendum rhoncus velit id iaculis.